Use Case: Proactive Control and Maintenance of laser-based manufacturing using Twin-based Data and Fog Computing

EMDIP (end user) is a middle-size company with engineering, technological, and manufacturing technological capabilities, with more than 80 employees. The ISVs, Nissatech and Netico, are challenged to create a Digital Twin, connect sensors and how data is collected to be further processed.

Missing transparency of laser cutting machines

The use case is driven by the missing transparency of laser cutting machines by external vendors, which means it is not enough information provided, and the vendor processes are far too complex. Those machines can be compared with black boxes of airplanes, which gather a lot of information, but any of it is not available to the pilot in the first place. Vice versa it is with machinery used in the workshop, data is not to be meant to support the manufacturer. Data is sacrificed to keep pull mechanisms active, so the manufacturer has to book the required (and cost-intensive) maintenance services by the machine vendor.

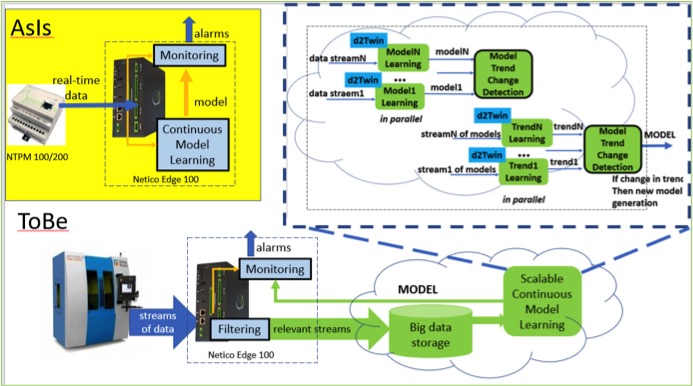

Novel Concept for EMDIPs Digital Twin

The use case designed a novel system in the area of continuous learning lined with past data as well as the dynamic models of the machine behaviour. The system is backed with High-Performance Computing Infrastructure and Fog.

High-quality laser cutting services

In order to provide high-quality laser cutting services is quite challenging due to the multi-criteria to be considered influencing the outputs. Several points, e.g. cutting edges, are needed to analyse the overall quality of the output. Further, criteria are meant to be resource-efficient, environmentally friendly, and sensitive to the nature of various resources, to find the best quality possible while reducing costs per unit.

Novel System Key Enabler

The Digital Twin is operated in the cloud and is one of the key enablers for the novel system:

- constantly learn and model the machine behaviour and supplement process changes

- create predictions based on the models and harmonize process parameters by reinforced learning mechanisms

- predict machine failures and issue preventive maintenance warnings

- specify target values for the machine to achieve the best quality and minimum resource utilisation.

Benefits for end user

By conducting the use case, EMDIP...

- automatic data updates of the Digital Twin

- reduced maintenance costs by 30% per year,

- increased Overall Equipment Effectiveness by 5%,

- and reduced waste by 3%.

The following were involved in the implementation

NETICO EMDIP

Nissatech Cloud Broker GmbH

University of Westminster STAM SLR